MASTER plastic injection mould is the core of our business for many years. MASTER has been an industry leader in the manufacturing of large industry plastic items. From heavy weighed pallet, to large sized garbage bin, we have virtually every application covered. You can be sure that with our many years experience, we can steer you in the direction, and help you develop the Industrial packaging mould, MASTER crate mold, MASTER plastic pallet mould as your needs.

Although the structure of the injection mould design and performance due to the variety of plastic, shape and type of plastics injection molding machine structure and the like may be different and changing, but the basic structure is the same.

2015年12月29日星期二

2015年12月25日星期五

Custom plastic injection moulding from MASTER

MASTER is one of the best Chinese custom molds manufacturer & supplier which offer good quality MASTER custom injection moulding based upon your correct specification or basic requirements on plastic molding technology.When you need to order Custom Moulds from China, please kindly offer the correct specification if you can. If not, please offer your basic requirement to get a quotation from us. Below is our contact information for your Custom Molds, also there is a Custom Molding list for your convenience to get a correct quotation.Of course,you can tell mold maker by every year, every month or every day how many pieces you need. Because the MASTER injection mold maker need this information to fix how many cavities on the quoted molds. And also it help mold maker to choose the correct steel, also it will help the mold maker to optimizer your mold custom cost.

2015年12月21日星期一

MASTER Plaster mould is engaged in plaster painted

Plaster mould is engaged in plaster painted friends or indispensable tool, quality made plaster friends are clearly made out of plaster, texture clear and smooth plaster mold is inseparable. Now the plast. Now the plaster mold material on the market there are PVC, resin, MASTER injection molding supplies rubber, vulcanized rubber and so on, then how the plaster mold what kind of material is good, judge the mold quality is qualified or not is very simple is whether the mold stripping, the mold is soft hard moderate. PVC, resin material market exists but the plaster mold is the two materials made of no, because the plaster mold is roasted in high temperature furnace, the two materials is baked not die at high temperature. So that is a resin, PVC material manufacturers must be lied to. Die really good material is pure rubber MASTER plastic injection mould material, mold the material for strong, soft hard moderate, easy demoulding.

2015年12月17日星期四

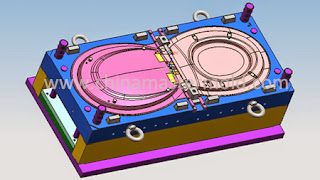

The mould consists of two primary components

The mould consists of two primary components, the MASTER injection mould (A plate) and the ejector mould (B plate). These components are also referred to as moulder and mould maker. Plastic resin enters the mould through a sprue or gate in the injection mould; the sprue bushing is to seal tightly against the nozzle of the injection barrel of the moulding machine and to allow molten plastic to flow from the barrel into the mould, also known as the cavity. The sprue bushing directs the molten plastic to the cavity images through channels that are machined into the faces of the A and B plates. These channels allow plastic to run along them, so they are referred to as runners. The molten plastic flows through the runner and enters one or more specialized gates and into the cavity geometry to form the desired part.

|

| Crate mould |

2015年12月13日星期日

MASTER injection molding process characteristics

MASTER custom injection moulding uses a ram or screw-type plunger to force molten plastic material into a mould cavity; this solidifies into a shape that has conformed to the contour of the mould. It is most commonly used to process both thermoplastic and thermosetting polymers, with the former being considerably more prolific in terms of annual material volumes processed. Thermoplastics are prevalent due to characteristics which make them highly suitable for plastic injection mould, such as the ease with which they may be recycled, their versatility allowing them to be used in a wide variety of applications, and their ability to soften and flow upon heating. Thermoplastics also have an element of safety over thermosets; if a thermosetting polymer is not ejected from the injection barrel in a timely manner, chemical crosslinking may occur causing the screw and check valves to seize and potentially damaging the injection moulding machine.

|

| plastic injection mold makers |

2015年12月9日星期三

MASTER injection molding Applications

MASTER injection molding supplies is used to create many things such as wire spools, packaging, bottle caps, automotive parts(auto moulding) and components, Gameboys, pocket combs, some musical instruments (and parts of them), one-piece chair(chair mould) and small tables, storage containers, mechanical parts (including gears), and most other plastic products available today. Injection moulding is the most common modern method of manufacturing parts; it is ideal for producing high volumes of the same object.

|

| chair mould |

2015年12月5日星期六

Parts to be MASTER injection moulds must be very carefully designed

Parts to be MASTER injection moulds must be very carefully designed to facilitate the moulding process,the material used for the part, the desired shape and features of the part, the material of the mould, and the properties of the moulding machine must all be taken into account. The versatility of injection mould design is facilitated by this breadth of design considerations and possibilities.

2015年12月1日星期二

Injection Mold Design Experience

I was engaged in injection mold structure design, it has designed household appliances, auto mould, electronic products mold. Design level is not necessarily high, but worked more live relatively complex only. Today, just nothing to do, with everyone under the joint discussion on the problem of gauge MASTER injection mould design. First, we get a product, do not rush parting, the most important thing is to first check the product structure, including draft, thickness, etc. moldable issues. Of course this is just for a person engaged in mold design, it may be more difficult. Because they may not know how to use it is more suitable for mold design products, which does not matter, just a process of their daily accumulation. When you finish a draft analysis products, wall thickness, as well as upside down in the direction of the mold where you basically already know the mold parting surface direction, and the position of the gate, of course, these ultimately keep customers acknowledgment.

2015年11月27日星期五

MASTER mold co.,Ltd. is a plastic company

MASTER mold co.,Ltd. is a plastic company specialized in injection mould design and manufacture with rich experience.Our company is a leading injection mould manufacturer in China with professional engineers and advanced equipments for mould making. We can develop, manufacture and test mould independently. At the same time, we have received recognition from domestic and oversea for our novelty products and confirm high quality mould through scientific management.Our main products are plastic rattan garden furniture mold, house ware moulds, pallet & crate moulds, pipe fitting moulds, thin-wall moulds, auto & motorcycle moulds, etc.

2015年11月23日星期一

MASTER injection mould design

Conventional injection mold design, mainly for two and experience in design, single two-dimensional engineering drawings have been very difficult to correct and detailed expression of the shape and structure of the product and can not be directly applied to CNC machining, analysis of the design process, long calculation period accuracy is poor. With the development of CAD/CAE/CAM technology, modern MASTER injection mould design approach is the designer directly on the computer three-dimensional model of the product, design and optimization of mold design three-dimensional model based on product, then NC The mold design three-dimensional model programming. This method makes product model design,MASTER mold maker from China, processing, programming and process design are to 3D data, data sharing, not only quickly improve design efficiency, but also to ensure quality and reduce costs. Injection mold design is a highly empirical issue, due to the limited experience in the design, difficult to apply a one-time three-dimensional modeling software direct design.

2015年11月19日星期四

thin wall injection molding machine and mold requirements

Small and light parts demand has become so MASTER thin wall injection molding

injection molding machine most need to increase performance. Depending on the size of the parts: the thin wall is usually caused by a wall thickness of less than 1mm portable electronic parts as defined. Large parts of the car, the thin wall can be 2mm. In short, thin-walled products requires a change process: higher pressure and speed, shorter cooling time, change part ejection and gate arrangement. Standard MASTER injection molding supplies machine for the production of a variety of thin wall products. The current performance of the new injection machine considerably more than 10 years ago. Material, gate technology and design advances, further broadening the standard injection machine performance filling of thin wall parts.

injection molding machine most need to increase performance. Depending on the size of the parts: the thin wall is usually caused by a wall thickness of less than 1mm portable electronic parts as defined. Large parts of the car, the thin wall can be 2mm. In short, thin-walled products requires a change process: higher pressure and speed, shorter cooling time, change part ejection and gate arrangement. Standard MASTER injection molding supplies machine for the production of a variety of thin wall products. The current performance of the new injection machine considerably more than 10 years ago. Material, gate technology and design advances, further broadening the standard injection machine performance filling of thin wall parts.

2015年11月15日星期日

MASTER lamp mold

Due to the physical and chemical interaction, and the plastic hardens into a certain shape and size of the plastic temperature keep constant. MASTER lamp mold Chair mold compression moulding is mainly used for molding the thermosetting plastic, such as phenolic moulding powder, urea formaldehyde and melamine formaldehyde molding powder, glass fiber reinforced plastic, epoxy resin, phenolic resin, silicone resin, polyimide, also forming unsaturated polyester material group sheet molding compound), BMC etc.. Chair mould in general, often with membrane structure according to the compression, under the mold, MASTER plaster mold the compression mould is divided into overflow type, not overflow type, semi overflow type three.

2015年11月12日星期四

Chinese plastic injection molding role?

MASTER chair mould : runner and gate is not in the parting line, directly on the product, Chinese plastic injection molding so to design a set of nozzle parting line, design is more complex, processing more difficult, usually depending on the product requirements and selection of fine nozzle system. The fixed mould part small inlet die is formed by three pieces of steel is also known as "the structure of the die mould". Three plate mold structure is small inlet die the most simple.

Or a constant temperature hot runner plate and heat pump mouth, no cold material release, runner and gate on the products directly, MASTER injection moulder so the channel does not need to release, this system is also known as the no water inlet system, which can save raw materials, suitable for raw materials, products more expensive higher requirements

2015年11月9日星期一

MASTER injection moulds

China plastic injection molding: runner and gate at the parting line, and products in the mold with demolding,MASTER injection moulds the most simple design, easy processing, low cost, so more people to use flood system operation. Plastic mold structure is divided into two parts: the fixed die and the moving die. With the active injection machine part is movable mould, injection molding machine injection in the end do not generally called the fixed mould. Because the fixed mould part of large nozzle mold generally formed by two pieces of steel is also known as "the structure of the mold two plate mold". MASTER injection mould Two plate mold structure is the most simple edge gate.

2015年11月6日星期五

China plastic injection molding

this system is also known as the no water inlet system, which can save raw materials, suitable for raw materials, products more expensive higher requirements, design and processing difficulties high cost, mould.China plastic injection molding hot runner system, also known as hot runner system, China plastic injection molding is mainly composed of a hot runner sleeve, hot runner plate, temperature control electric box. Our common hot runner system has a single point and multi-point hot runner hot runner in two forms.chair mould: is the earliest one of the molding method. Compression molding the plastic directly into the open mold cavity with a certain temperature, then the mold is closed, chair mould in heat and pressure melt into the flowing state of plastics

2015年11月3日星期二

MASTER plastic pallet mould

plastic barrelthan master mold and other manufacturers developed plasti

2015年10月31日星期六

MASTER pipe fitting mould

Mold making; MASTER pipe fitting mould under the action of external force and the blank into a

certain shape and size of the workpiece tool. Widely used for punching,

forging, cold forging, extrusion, powder metallurgy pressing, pressure

casting, as well as engineering plastics, rubber, ceramics and other

products of the compression molding or injection molding. Mold production

has a contour or shape of the inner cavity of specific application with

the shape of cutting edge, can make the blank according to the contour

shape separate mold making application internal shape to make the blank

to obtain three-dimensional shape corresponding. Mold making usually

includes two parts: the fixed die and the moving die, the two can be

combined. Mold making apart and taking out the product, the blank is

folded into the mould cavity forming. Mold making is

a precision tool, complex shape, bearing blank expansion force, have

higher requirements on the structure strength, stiffness, surface

hardness, surface roughness and machining precision, development level

of mold manufacturing is an important sign of the level of

manufacturing. There are many kinds of mold making, mold making

according to the processing object and process can be divided into: mold

processing of metal.

2015年10月28日星期三

injection mold maker

injection mold maker rattan garden furniture mould: the injection pressure is provided by a hydraulic system of injection system. The h. The hydraulic cylinder pressure transfer to the plastic melt through the screw injection molding machine, plastic melt in the pressure driven flow into the mold through the nozzle, vertical injection molding machine, for part of the mould is also the sprue, runner, and the mainstream, the gate into the mold cavity, the process is the process of injection, or the filling process. Stress is to overcome the melt flow in the process of resistance, or conversely, flow resistance in the process of injection molding machine pressure needed to offset the filling process, to ensure smooth.

MASTER plastic rattan garden furniture mold in the process of injection molding, injection molding machine nozzle pressure maximum, to overcome the melt flow resistance in the process of. Subsequently, pressure along the flow length to melt the front wavefront at gradually reduced, if the inside of the cavity exhaust is good, the melt front final pressure is atmospheric pressure.

2015年10月25日星期日

MASTER thin wall injection molding

Many master plastic rattan garden furniture mould effect of melt factors, summed up in 3 categories: the material factors, such as the type of plastic, viscosity; structural factors, such as type, plastic rattan garden furniture mold number and position of the gating system, the mold cavity shape and product thickness; elements of technology molding. Injection time here refers to the plastic melt filled cavity required time, do not include mold opening and closing, and other auxiliary time. Although the injection time is very short, the influence of molding cycle is also very small, but the injection time adjustment has a great effect on pressure control gate, sprue and cavity. Injection time reasonable help melt ideal filling, but also improve the surface quality of the products and has a very important significance to reduce the size tolerance.

MASTER thin wall injection molding injection time is much lower than the cooling time, about the cooling time of 1/10 ~ 1/15, this rule could be used to predict the plastic parts molding time for all. In mold flow analysis, only when the melt is completely by the screw rotating drive filled cavity case, injection timing for thin-wall injection molding in the injection time is equal to the set of process conditions. If there are filled in the cavity of the screw holding switch, then the results will be greater than the process conditions.

2015年10月22日星期四

MASTER make plastic molds

The makers of the plastic injection mold and master the pot mold: products all he hascertain service life, of course, master pot mold is not exception. The makers of the plastic injection mold and grasp the method of using pot mold correctly, grasp the pot mold can prolong its life in a certain extent. Plastic tray also has its proper use. Forklift driver for the use of plastic pallets to turnover of goods should have good driving skills, MASTER pot mold can make the forklift in the hand easily manipulated, avoid strong collision occurred directly with plastic tray, the production, transportation, storage and circulationfields, MASTER make plastic molds is considered to be one of the logistics industry intwentieth Century two key innovation. The makers of the plastic injection mold and master the pot mold as equipment handling, storage and transportation of importantlogistics operation process, supporting the use of forklift plays an important role in modern logistics. In order to plastic tray can play its role and prolong the service life,grasp the plastic mold in the actual operation process should be correct, regulate the use of IC plastic pallet, avoid unnecessary losses.

2015年10月19日星期一

MASTER injection moulding companies

New Vision plastic mold generally die and plastic mold by moving the

fixed mold composed of two parts, the movable die is mounted on the

movable platen injection molding machine, scheduled to die is mounted on

the stationary platen injection molding machine. During injection

molding of the movable die and the fixed die casting MASTER injection moulding companies system and constitutes a closed cavity mold when the fixed mold and the movable mold to remove the separated plastics. Although

the structure of the mold and performance of varieties of plastic,

shape, and configuration and the type of plastics injection molding

machine may be different and changing, but the basic MASTER pe pipe fitting mold

structure is the same. Die mainly by gating system, thermostat

system, molded parts and structural parts. Gating system and molded

parts which are in direct contact with the plastic part, and with the

plastics and products change, the mold is the most complex and the

biggest change, the most demanding part of the process finish and

accuracy.

2015年10月16日星期五

MASTER mould maker

Mold design one, the design of the mold before the mold is opened

first pop 0.05-0.1mm, easy blowing, to avoid sticking to the former

model; 2, inserts and inserts, inserts and columbium MASTER mould maker

mating surfaces of every mill exhaust ducts number four, according to

the characteristics of the product structure, materials, and beer;, depth

is defined as 0.015mm; 3, carrying water to do the entire mold

reasonable, adequate, with as much as a principle, it should be done

every inserts carrying plastic drawer mold water how many, the MASTER injection moulding companies choice of a reasonable mold material. In the last election material size necessary to bear.

2015年10月13日星期二

custom injection moulding

custom injection moulding thermoplastic mold also used some special such as the difficulty of molten thermoplastic such as poly (vinyl fluoride) blank (cold molding), high optical performance of resin lenses, slightly foaming nitrocellulose automobile steering wheel . Compression molds mainly by the cavity, chamber, guiding mechanism, pushing member, heating systems and other components. Pressure injection molds are widely used in packaging electrical components aspect. Compression molds used in the manufacture of materials and injection mold maker basically the same.

2015年10月9日星期五

Custom plastic mold

Custom plastic mold Is mainly used for forming a class of thermosetting plastic mold, its corresponding device is a pressure molding machine. The plastic properties of compression molding method, the mold is heated to a molding temperature (typically 103 ° -108 °), then good measure pressure plastic powder into the mold cavity and feeding room, closed mold, high fever, high pressure in the plastic It was softening viscous flow, after a certain time curing stereotypes, into a desired shape of the article. Pressure china plastic injection molding and compression molding except that no separate feeding room, before forming the first closed mold, plastic interior completion in the feed preheat was viscous flow state, under pressure to adjust to squeeze into the mold cavity, hardening molding.

2015年7月2日星期四

Plastic container molding

MASTER Engineering and Design Team does best: finding innovative and creative solutions to help speed customers’ injection molded products to market.

The team uses project management through out the design process to document customer specific requirements and integrate them into the mold product design.

Using parametric fundamentals of plastic injection mould design, the team creates tool design models that have complete associativity throughout all of the different components of an assembly.pvc pipe fitting mould This means that both major and minor changes to a product can be made and reviewed with the customer through all stages of design and build of a precision plastic mould. Design changes are communicated electronically in real time to the machine programmers who are shaping the steel and can be communicated to customers via on-line web and video conferencing.

Ycheng’s Engineers routinely recommend solutions to customers that can increase product performance, product lifecycle, reliability, and profitability both for Ycheng, and for the customer.

The team uses project management through out the design process to document customer specific requirements and integrate them into the mold product design.

Using parametric fundamentals of plastic injection mould design, the team creates tool design models that have complete associativity throughout all of the different components of an assembly.pvc pipe fitting mould This means that both major and minor changes to a product can be made and reviewed with the customer through all stages of design and build of a precision plastic mould. Design changes are communicated electronically in real time to the machine programmers who are shaping the steel and can be communicated to customers via on-line web and video conferencing.

Ycheng’s Engineers routinely recommend solutions to customers that can increase product performance, product lifecycle, reliability, and profitability both for Ycheng, and for the customer.

2015年6月28日星期日

Plastic mold manufacturer

1. Dimensional accuracy and appearance request.

2. Requires high quality appearance, but dimensional accuracy low of plastic products, such as toys thin wall injection molding .

3. Functional plastic products and strict dimensional accuracy requirements.

4. Appearance and dimensional accuracy are very strict for the plastic products, such as cameras.

5. Have reasonable draft angle? because draft angle affect quality of the injection molding product.

6. Plastic material shrinkage and cavity number.

2. Requires high quality appearance, but dimensional accuracy low of plastic products, such as toys thin wall injection molding .

3. Functional plastic products and strict dimensional accuracy requirements.

4. Appearance and dimensional accuracy are very strict for the plastic products, such as cameras.

5. Have reasonable draft angle? because draft angle affect quality of the injection molding product.

6. Plastic material shrinkage and cavity number.

2015年6月24日星期三

Plastic container molding

1. Tooling Lead Time is as Short as Possible

2. Best Quality at a Reasonable Price

3.thin wall injection molding Always have 1 contact person during the whole project for both mold and molding . Every week update the working process to clients.

4. Be on your service 24 hours, and make a specific quotation for you within a day .

2. Best Quality at a Reasonable Price

3.thin wall injection molding Always have 1 contact person during the whole project for both mold and molding . Every week update the working process to clients.

4. Be on your service 24 hours, and make a specific quotation for you within a day .

2015年6月20日星期六

Make plastic molds

We offer a complete in house service. Starting at component design and development, mould design and onto manufacturing of moulds. We have 30 years tooling experience in the field of Injection tooling, blow moulds and aluminum die casting, we design high-tech moulds for intricate components, including high speed automatic unscrewing moulds, incorporation of hot runner injection systems.

In order to provide quality services, we have made a substantial investment in first rate CAD/CAM state of the art design software. Including full 3D (three dimensional) solid and surface modeling, presentation shading, drafting and dimensioning,Plastic injection mold makers intricate split line generation and mould build libraries for all the major suppliers.

We also offer a total project management service after the design phase, this service includes having development components machined or grown samples made, to Manufacturing of the moulds. We have just launched our own CNC orientated toolroom to manufacture high quality, reasonably price moulds, and light engineering machined parts.

We also maintain and service moulds including mould report and corrective action. We have recently become a member of the Toolmakers Association of South Africa and have been benchmarked by a world renowned German engineering University.

In order to provide quality services, we have made a substantial investment in first rate CAD/CAM state of the art design software. Including full 3D (three dimensional) solid and surface modeling, presentation shading, drafting and dimensioning,Plastic injection mold makers intricate split line generation and mould build libraries for all the major suppliers.

We also offer a total project management service after the design phase, this service includes having development components machined or grown samples made, to Manufacturing of the moulds. We have just launched our own CNC orientated toolroom to manufacture high quality, reasonably price moulds, and light engineering machined parts.

We also maintain and service moulds including mould report and corrective action. We have recently become a member of the Toolmakers Association of South Africa and have been benchmarked by a world renowned German engineering University.

2015年6月16日星期二

Thin wall injection molding

Details about the plastic injection mold products

1.Material of the plastic injection mold products:plastic injection mould Nylon, ABS, PMMA, PP, POM, PP, PE, PC, PBT, PA, PSU, TPU, TPE, etc..

2.Scope of moulding products : Automotive plastic accessories, Computer plastic accessories, Architecture plastic accessories, Household plastic accessories , etc.

1.Material of the plastic injection mold products:plastic injection mould Nylon, ABS, PMMA, PP, POM, PP, PE, PC, PBT, PA, PSU, TPU, TPE, etc..

2.Scope of moulding products : Automotive plastic accessories, Computer plastic accessories, Architecture plastic accessories, Household plastic accessories , etc.

2015年6月12日星期五

Plastic mold manufacturer

We have always been insisting on the idea that employees are the basis to ensure high quality products and realize the development of both employees and company. So we have enrolled lots of mould technologist, managing talents, and professional engineers.

china plastic injection molding always keep Layout at the top, push modernized management system in china mold making. Go in for zero default. Make sure quality and techniques in the highest way. Therefore, We dedicate to explore the new field and make innovation and progress continually to be a professional china mold maker. keep developing on the present basis in order enhance our level of mold designing and mold manufacturing, and providing medium price high quality mold .

china mould maker.China mold factory, China toolmaker, china mold supplier, china injection mold company, injection mold….more

china plastic injection molding always keep Layout at the top, push modernized management system in china mold making. Go in for zero default. Make sure quality and techniques in the highest way. Therefore, We dedicate to explore the new field and make innovation and progress continually to be a professional china mold maker. keep developing on the present basis in order enhance our level of mold designing and mold manufacturing, and providing medium price high quality mold .

china mould maker.China mold factory, China toolmaker, china mold supplier, china injection mold company, injection mold….more

2015年6月8日星期一

Garden plastic chairs mold

MASTER mainly exports high quality plastic injection molds and plastic injection parts for oversea customers of all over the world.

MASTER is specialized in plastic injection molds and injection plastic products developing ,plastic mold manufacturer designing and manufacturing, we also supply our clients with EDM and OEM services for their different sizes customized plastic products. Our current products involves in auto parts,Houseware&Toy parts, Electronic&Electrical parts, medical equipment, computer parts, communication parts , automation equipment and some other areas plastic parts. The success of our business in the past years comes from our commitment to build mutually beneficial and win-win relationships with our partners and clients. Honesty and integrity are the most important principles of the company.

MASTER is specialized in plastic injection molds and injection plastic products developing ,plastic mold manufacturer designing and manufacturing, we also supply our clients with EDM and OEM services for their different sizes customized plastic products. Our current products involves in auto parts,Houseware&Toy parts, Electronic&Electrical parts, medical equipment, computer parts, communication parts , automation equipment and some other areas plastic parts. The success of our business in the past years comes from our commitment to build mutually beneficial and win-win relationships with our partners and clients. Honesty and integrity are the most important principles of the company.

2015年6月2日星期二

Injection moulding companies

Plastic parts are always designed with a taper or draft in the direction of mold movement to allow part ejection or removal from the mold. Since plastics shrink when cooled, plastic rattan garden furniture is common for parts to shrink (or grip tightly) to cores. A good definition for draft would be: the degree of taper of a side wall or rib needed to allow the molded plastic part to be removed from the metal mold. Without proper draft, plastic parts may be difficult to remove from the mold. A draft angle of 1/2 degrees is regarded as minimum for most applications. Draft angles of 1 1/2 to 2 degrees per side are considered normal for plastic injection molding.

2015年5月29日星期五

Custom injection moulding

plastic injection molding is the primary process for manufacturing plastic parts. cabinet mould is known to be a very versatile and economical material that is uesd in many appliacations .Although the tooling is expensive ,the cost per part is very low .Complex geometries are possible and limited only to mold manufacturability .Your computer monitor ,mouse and keyboard are injection molded plastics.

2015年5月26日星期二

Plastic pallet mould

Plastic rattan garden furniture mold Imitation series is our new project which has good reputation all over word,especially for the rattan imitation garden chair,table,sofa,etc.Plastic rattan garden furniture is widely used instead of hand-made MASTER custom injection moulding because of many advantages,like UV-resistant, efficient production,light weight and lower cost.We have already made many kinds of rattan imitation mould,like rattan table,rattan chair,rattan sofa,rattan cabinet,dustbin,toilet brush,drawer,tissue box and so on.

2015年5月25日星期一

Plastic injection mold makers

Plastic injection mold makers process uses a granular plastic that is gravity fed from a hopper. A screw-type plunger forces the material into a heated chamber, called a barrel, where plastic injection toy mould is melted. The plunger continues to ad- vance, pushing the polymer through a nozzle at the end of the barrel that is pressed against the mold. The plastic enters the mold cavity through a gate and runner system. After the cavity is filled, a holding pressure.

2015年5月21日星期四

Plastic injection mould

Injection molding is used for manufacturing a wide variety of parts, from small components like AAA battery boxes to large components like truck body panels. Once a component is designed, a mold is made and pre- cision machined to form the features of the desired part. Injection mold maker when a thermoplastic or thermoset plastic material is fed into a heated barrel, mixed, and forced into the metal mold cavity where it cools and hardens before being removed.

2015年5月17日星期日

Plastic rattan garden furniture mold

We conceive, design, build, and test every mold so it meets the exact tolerances and specifications you require. If you have a mold already designed, we’ll still run it by our engineers to make certain we produce the best possible plastic injection mold makers manufactured for your company.

Our high quality molds are constructed using the highest-grade materials. This increases mold longevity and avoids plastic mold manufacturer waste from molds that lose their tolerances during the production process.

Our machinists have designed and developed some of the most intricate and creative plastic injection molds in the industry.

We strictly adhere to high-grade steel for the plastic injection mold industry. We don’t use soft metals like aluminum and we don’t build molds for any crafts like chocolate or ceramics.

Our high quality molds are constructed using the highest-grade materials. This increases mold longevity and avoids plastic mold manufacturer waste from molds that lose their tolerances during the production process.

Our machinists have designed and developed some of the most intricate and creative plastic injection molds in the industry.

We strictly adhere to high-grade steel for the plastic injection mold industry. We don’t use soft metals like aluminum and we don’t build molds for any crafts like chocolate or ceramics.

2015年5月14日星期四

Injection mould design

MASTER mold co.,Ltd. is a plastic company specialized in injection moulds design and manufacture with rich experience.Our company is a leading china plastic injection molding manufacturer in China with professional engineers and advanced equipments for mould making. We can develop, manufacture and test mould independently. At the same time, we have received recognition from domestic and oversea for our novelty products and confirm high quality mould through scientific management.

2015年5月3日星期日

injecion mold

Vertical Plastic injection mold makers : which is characterized by the axis of the clamping device and the injection device was arranged in line and perpendicular to the ground. china plastic injection molding has a small footprint, easy mold assembly and disassembly, insert easy to install, the more uniformly plasticized material from falling into the hopper, easy to automate and multiple automatic line management and so on. The disadvantage is easy to fall off the top of the article, which require manual or other methods out, not easy to achieve fully automated operation and large injection products; machine body, feeding, maintenance inconvenience.

2015年4月23日星期四

Plastic injection toy mould is composed of a movable die and mold is composed of two parts, the dynamic model is installed in the moving platen of injection molding machine, die is mounted in a fixed template for injection molding machine. In the injection molding die and mold closing of gating system and the mold cavity, when the movable mould and the fixed mould separation in order to remove the plastic products.

模具的结构虽然由于塑料品种和性能、塑料制品的形状和结构以及注射机的类型等不同而可能千变万化,但是基本结构是一致的。模具主要由浇注系统、调温系统、成型零件和结构零件组成。其中浇注系统和成型零件是与塑料直接接触部分,并随塑料和制品而变化,是塑模中最复杂,变化最大,要求加工光洁度和精度最高的部分。

Although the plastic mould structure, varieties and properties of plastic products shape and structure and the type of injection molding machine and the myriads of changes may be different, but the basic structure is the same. Mainly by die casting system, cooling system, molding parts and structural parts. The gating system and molding parts is a direct contact with the plastic parts, and varies with plastics and products, is one of the most complex, plastic mold manufacturer changes, requirements for finish machining and high precision.

2015年4月20日星期一

Mold design, parting choices is critical, which determines the structure of the MASTER thin wall injection molding . Should choose principles and MASTER plastic molding factory parts in accordance with the requirements of sub-surface to select the sub-surface. The plastic parts for the machine frame, surface quality, no special requirements, but in the process of winding finger contact face and workers more, so naturally formed on the end face of the best fillet. In addition, the part height 12mm, and the cross-sectional shape perpendicular to the axis is relatively simple and standardized.

2015年4月16日星期四

MASTER plastic injection mold makers

MASTER plastic injection mold makers

2015年4月7日星期二

MASTER:professional and trustworthy

MASTER:professional and trustworthy

2015年4月2日星期四

Plastic molds making

plastic molds

2015年3月26日星期四

Injection Molding

Injection Molding

china plastic injection molding , also known as injection molding, which is a molding method and injection molding. Advantages of injection molding method is the production speed, high efficiency, operation can be automated, color varieties, shapes can be from simple to complex, size can be big to small, and product size precision, easy replacement product, it can become a complex shape parts, Custom plastic mold is suitable for mass production and field forming complex shapes products. At a certain temperature, stirred by the screw completely molten plastic material, with high pressure, into the mold cavity, after solidified by cooling to obtain a molded product of the method. This method is suitable for mass production of complex shape member, is one of important processing methods.

2015年3月17日星期二

MASTER injection mold maker

MASTER injection mold maker

2015年3月6日星期五

injection mould design further development of new technologies

injection mould design , in order to ensure the rapid development of a high-tech industry in the mold industry, mold industry must also be a higher level of many common technologies, should continue to develop and promote the use and application of high-tech active. They are mainly:

Developed with independent intellectual property rights, China's national conditions, with high levels of mold design, mold processing and business management software, and constantly improve the intelligence, the degree of integration software.

Promote the use of high-speed, high precision technology and the development of appropriate equipment.

High-speed machining and finishing, including processing power and composite processing. In the next 15 years or so, China's machine tool industry should gradually die industry to provide for high-speed finishing of the mold corresponding equipment, if possible, MASTER injection mould design the proposed development with independent intellectual property rights, the accuracy can reach 0.0001mm precision mold manufacturing equipment.

Rapid prototyping and rapid economic mold manufacturing and further development of new technologies to improve and applications.

To develop and promote information technology, digital technology. Such as reverse engineering, concurrent engineering, agile manufacturing R & D and application technologies; including large progressive die, high-precision, high-complexity, injection mould design design and manufacture of advanced technology research and development; including stamping process planning system, mold research-based surface design system, injection moulding companies forming analysis system, mold design system, cam system and stamping mold expert consultation system body mold design and manufacture of digital systems; mold integration, flexible and automatic processing technology and network and virtual technology.

Mold manufacturing of new technology and new technology. Saving mold manufacturing, materials technology, mold heat treatment, surface finishing and surface treatment of new technology. Developing high-performance mold material, serialization and the correct selection.

China's mold industry in addition to continue to increase production capacity, but also to focus on the future adjustments and improve the technical level of development within the industry structure.

订阅:

博文 (Atom)