1. Dimensional accuracy and appearance request.

2. Requires high quality appearance, but dimensional accuracy low of plastic products, such as toys thin wall injection molding .

3. Functional plastic products and strict dimensional accuracy requirements.

4. Appearance and dimensional accuracy are very strict for the plastic products, such as cameras.

5. Have reasonable draft angle? because draft angle affect quality of the injection molding product.

6. Plastic material shrinkage and cavity number.

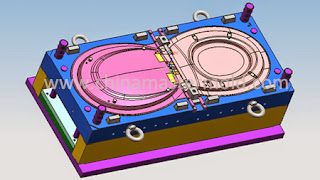

Although the structure of the injection mould design and performance due to the variety of plastic, shape and type of plastics injection molding machine structure and the like may be different and changing, but the basic structure is the same.

2015年6月28日星期日

2015年6月24日星期三

Plastic container molding

1. Tooling Lead Time is as Short as Possible

2. Best Quality at a Reasonable Price

3.thin wall injection molding Always have 1 contact person during the whole project for both mold and molding . Every week update the working process to clients.

4. Be on your service 24 hours, and make a specific quotation for you within a day .

2. Best Quality at a Reasonable Price

3.thin wall injection molding Always have 1 contact person during the whole project for both mold and molding . Every week update the working process to clients.

4. Be on your service 24 hours, and make a specific quotation for you within a day .

2015年6月20日星期六

Make plastic molds

We offer a complete in house service. Starting at component design and development, mould design and onto manufacturing of moulds. We have 30 years tooling experience in the field of Injection tooling, blow moulds and aluminum die casting, we design high-tech moulds for intricate components, including high speed automatic unscrewing moulds, incorporation of hot runner injection systems.

In order to provide quality services, we have made a substantial investment in first rate CAD/CAM state of the art design software. Including full 3D (three dimensional) solid and surface modeling, presentation shading, drafting and dimensioning,Plastic injection mold makers intricate split line generation and mould build libraries for all the major suppliers.

We also offer a total project management service after the design phase, this service includes having development components machined or grown samples made, to Manufacturing of the moulds. We have just launched our own CNC orientated toolroom to manufacture high quality, reasonably price moulds, and light engineering machined parts.

We also maintain and service moulds including mould report and corrective action. We have recently become a member of the Toolmakers Association of South Africa and have been benchmarked by a world renowned German engineering University.

In order to provide quality services, we have made a substantial investment in first rate CAD/CAM state of the art design software. Including full 3D (three dimensional) solid and surface modeling, presentation shading, drafting and dimensioning,Plastic injection mold makers intricate split line generation and mould build libraries for all the major suppliers.

We also offer a total project management service after the design phase, this service includes having development components machined or grown samples made, to Manufacturing of the moulds. We have just launched our own CNC orientated toolroom to manufacture high quality, reasonably price moulds, and light engineering machined parts.

We also maintain and service moulds including mould report and corrective action. We have recently become a member of the Toolmakers Association of South Africa and have been benchmarked by a world renowned German engineering University.

2015年6月16日星期二

Thin wall injection molding

Details about the plastic injection mold products

1.Material of the plastic injection mold products:plastic injection mould Nylon, ABS, PMMA, PP, POM, PP, PE, PC, PBT, PA, PSU, TPU, TPE, etc..

2.Scope of moulding products : Automotive plastic accessories, Computer plastic accessories, Architecture plastic accessories, Household plastic accessories , etc.

1.Material of the plastic injection mold products:plastic injection mould Nylon, ABS, PMMA, PP, POM, PP, PE, PC, PBT, PA, PSU, TPU, TPE, etc..

2.Scope of moulding products : Automotive plastic accessories, Computer plastic accessories, Architecture plastic accessories, Household plastic accessories , etc.

2015年6月12日星期五

Plastic mold manufacturer

We have always been insisting on the idea that employees are the basis to ensure high quality products and realize the development of both employees and company. So we have enrolled lots of mould technologist, managing talents, and professional engineers.

china plastic injection molding always keep Layout at the top, push modernized management system in china mold making. Go in for zero default. Make sure quality and techniques in the highest way. Therefore, We dedicate to explore the new field and make innovation and progress continually to be a professional china mold maker. keep developing on the present basis in order enhance our level of mold designing and mold manufacturing, and providing medium price high quality mold .

china mould maker.China mold factory, China toolmaker, china mold supplier, china injection mold company, injection mold….more

china plastic injection molding always keep Layout at the top, push modernized management system in china mold making. Go in for zero default. Make sure quality and techniques in the highest way. Therefore, We dedicate to explore the new field and make innovation and progress continually to be a professional china mold maker. keep developing on the present basis in order enhance our level of mold designing and mold manufacturing, and providing medium price high quality mold .

china mould maker.China mold factory, China toolmaker, china mold supplier, china injection mold company, injection mold….more

2015年6月8日星期一

Garden plastic chairs mold

MASTER mainly exports high quality plastic injection molds and plastic injection parts for oversea customers of all over the world.

MASTER is specialized in plastic injection molds and injection plastic products developing ,plastic mold manufacturer designing and manufacturing, we also supply our clients with EDM and OEM services for their different sizes customized plastic products. Our current products involves in auto parts,Houseware&Toy parts, Electronic&Electrical parts, medical equipment, computer parts, communication parts , automation equipment and some other areas plastic parts. The success of our business in the past years comes from our commitment to build mutually beneficial and win-win relationships with our partners and clients. Honesty and integrity are the most important principles of the company.

MASTER is specialized in plastic injection molds and injection plastic products developing ,plastic mold manufacturer designing and manufacturing, we also supply our clients with EDM and OEM services for their different sizes customized plastic products. Our current products involves in auto parts,Houseware&Toy parts, Electronic&Electrical parts, medical equipment, computer parts, communication parts , automation equipment and some other areas plastic parts. The success of our business in the past years comes from our commitment to build mutually beneficial and win-win relationships with our partners and clients. Honesty and integrity are the most important principles of the company.

2015年6月2日星期二

Injection moulding companies

Plastic parts are always designed with a taper or draft in the direction of mold movement to allow part ejection or removal from the mold. Since plastics shrink when cooled, plastic rattan garden furniture is common for parts to shrink (or grip tightly) to cores. A good definition for draft would be: the degree of taper of a side wall or rib needed to allow the molded plastic part to be removed from the metal mold. Without proper draft, plastic parts may be difficult to remove from the mold. A draft angle of 1/2 degrees is regarded as minimum for most applications. Draft angles of 1 1/2 to 2 degrees per side are considered normal for plastic injection molding.

订阅:

博文 (Atom)