1. Dimensional accuracy and appearance request.

2. Requires high quality appearance, but dimensional accuracy low of plastic products, such as toys thin wall injection molding .

3. Functional plastic products and strict dimensional accuracy requirements.

4. Appearance and dimensional accuracy are very strict for the plastic products, such as cameras.

5. Have reasonable draft angle? because draft angle affect quality of the injection molding product.

6. Plastic material shrinkage and cavity number.

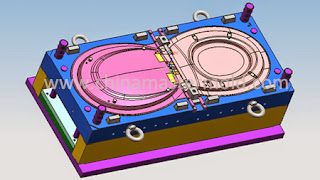

Although the structure of the injection mould design and performance due to the variety of plastic, shape and type of plastics injection molding machine structure and the like may be different and changing, but the basic structure is the same.

2015年6月28日星期日

2015年6月24日星期三

Plastic container molding

1. Tooling Lead Time is as Short as Possible

2. Best Quality at a Reasonable Price

3.thin wall injection molding Always have 1 contact person during the whole project for both mold and molding . Every week update the working process to clients.

4. Be on your service 24 hours, and make a specific quotation for you within a day .

2. Best Quality at a Reasonable Price

3.thin wall injection molding Always have 1 contact person during the whole project for both mold and molding . Every week update the working process to clients.

4. Be on your service 24 hours, and make a specific quotation for you within a day .

订阅:

博文 (Atom)